KPN is a leading provider of telecommunications and IT services in the Netherlands. According to the company, since 2015 it has gradually limited its negative impact on the environment, as it only uses green energy. KPN is committed to continue setting goals that will be more eco-friendly. As the company wants to create a more prosperous and cleaner world, they are looking to come up with a solution to provide a more comprehensive input regarding the origin and footprint our food has.

The Challenge

Nowadays, consumers are being well educated on the hazards of using pesticides and other industrial processes that pose a health hazard. They want to know more about the origin of their food. Customers want to have a better understanding of where and more importantly how their fruits and vegetables were grown.

On the other hand, there is the government that urges farmers to reinvent their production to employ a more sustainable approach that guarantees food safety. To adjust to the circular economy and amend the current process, farmers need more real time, detailed insights regarding the waste processes of their production.

Currently, there is no mechanism that can track and validate products’ origin. A tool that can monitor their footprint and ensure that they are safe. There is a lack of uniform method to provide real numbers. Mostly, there are rather estimations regarding the contribution farmers have to circular and sustainable production.

An Inspired Action

Through the Enterprise Europe Network, KPN is looking for internet-of-things solutions to address the challenge and provide a deep input. The Dutch telecom provides assets such as mobile communication and LoRa. It is now looking for partners to make use of its networks in order to exchange data with crops during all phases in the supply chain. This data will lead to better insights about the origin and footprint of fruits and vegetables. The company is on the road to find an economically and sustainable way to that process.

KPN is basically looking for partners who are able to develop the necessary ecosystem needed to distribute the required information.

Our Reaction

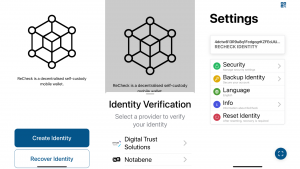

ReCheck’s blockchain engine can be easily integrated with different software systems to create digital fingerprints and time stamps on Distributed Ledger Technology (DLT). We can build an environment that guarantees the secure exchange of sensitive data, where each transaction is digitally signed.

Our functionalities allow for easy and secure recording, storing and sharing of production related data. The blockchain layer ensures that data is validated and so, alteration and corruption are practically impossible. Consumers will be able to learn about the whole life cycle of their product. Ultimately, blockchain technology can increase efficiency, value and transparency for the whole supply chain.